As a new brand, a lot of you may be asking yourselves; why choose CTE Carbon Composites over our competitors?

Peer Competitors (non-exhaustive list):

In terms of manufacturing process, the two main types are:

If you have any questions at all, please feel free to Contact Us.

- Our parent company, CCYS Hi-Tech International Co., Ltd, responsible for R&D and Manufacturing, was established over 5 decades ago and is one of the largest manufacturers of OE chassis & friction components in the world, with a gross annual revenue over US$60m

- Our partner company, MFactory Competition Products, responsible for R&D, Marketing and Distribution, was established over 2 decades ago and is one of the largest manufacturers of aftermarket drivetrain components in the world, with a gross annual revenue over US$10m

- By combining the resources and decades of knowledge from both companies, this puts us in a strong position to establish CTE Carbon Composites as a "dominant player" in the consumer-grade composites market

Peer Competitors (non-exhaustive list):

- Alcon CCX (ST Pre-2024)

- AP Racing/Stillen CCM-X (Brembo/SGL)

- Brembo/SGL CCM-R

- Surface Transforms (ST)

- Mass-Market OE

- Brembo/SGL CCB/CCM

- Mainland China CCM's

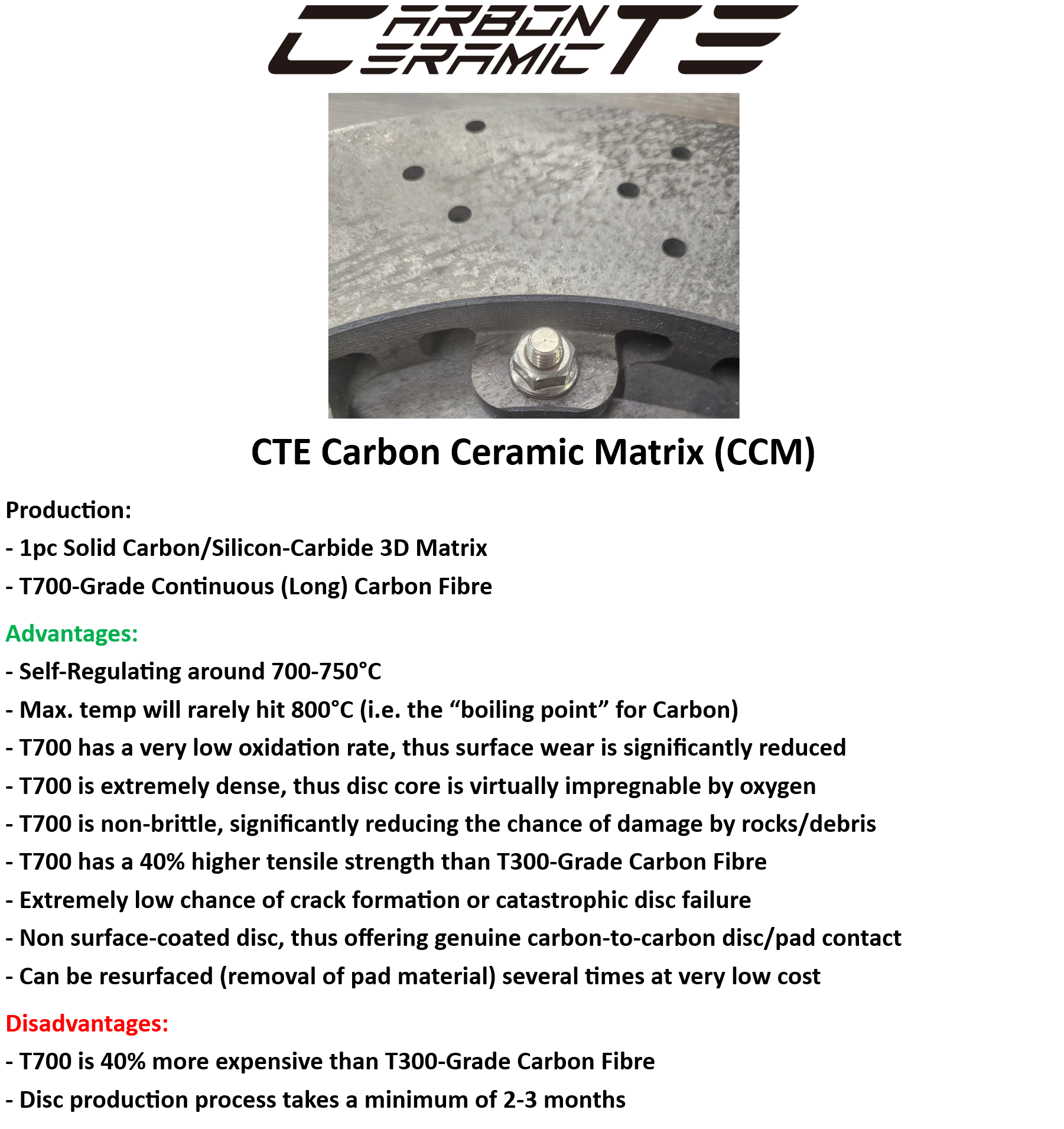

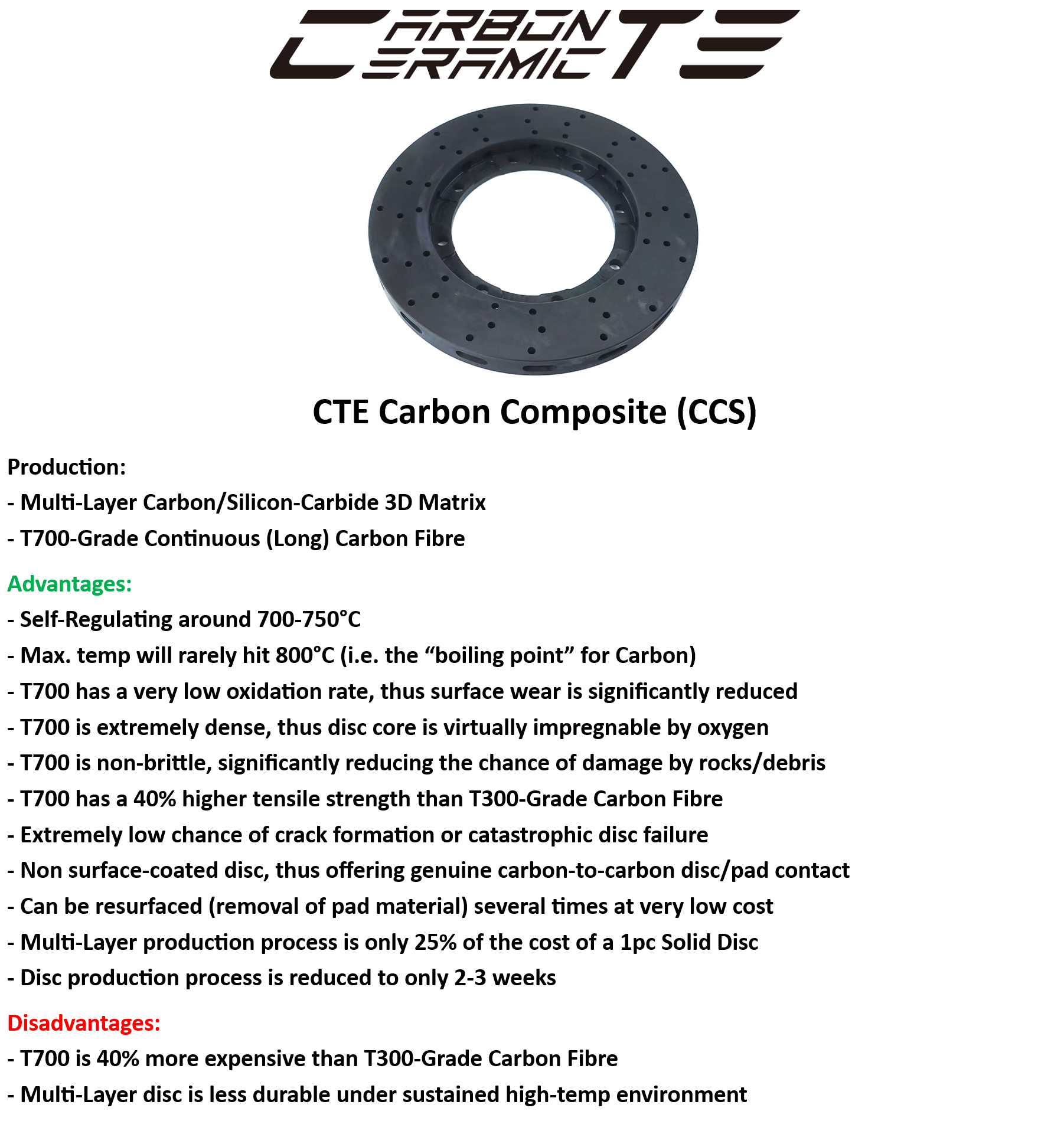

In terms of manufacturing process, the two main types are:

- CCB - These discs consist of an inner core constructed from a ceramic material reinforced with carbon fibre (CFRC), which then have an additional outer ceramic friction layer added. These are the "original" type of Carbon Ceramic Brakes and are very prone to premature wear and/or cracking caused by either surface damage to the friction layer, or by oxidation of the friction layer (caused by high temperatures). Of course, poor manufacturing methods/QC also contribute to premature wear. If you notice a Carbon Ceramic Brake disc with surface cracks (even on a brand-new disc), stay well clear of it

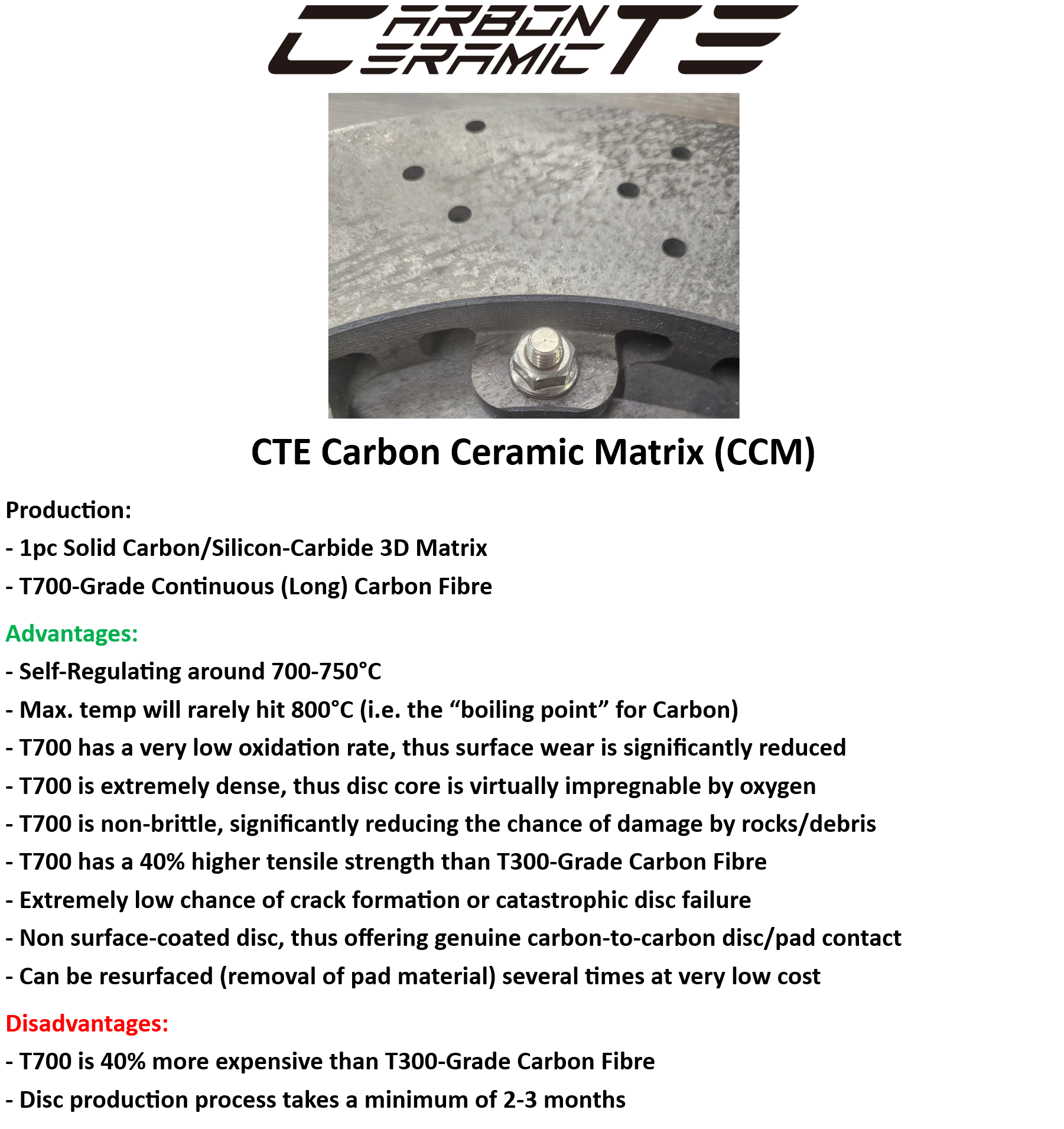

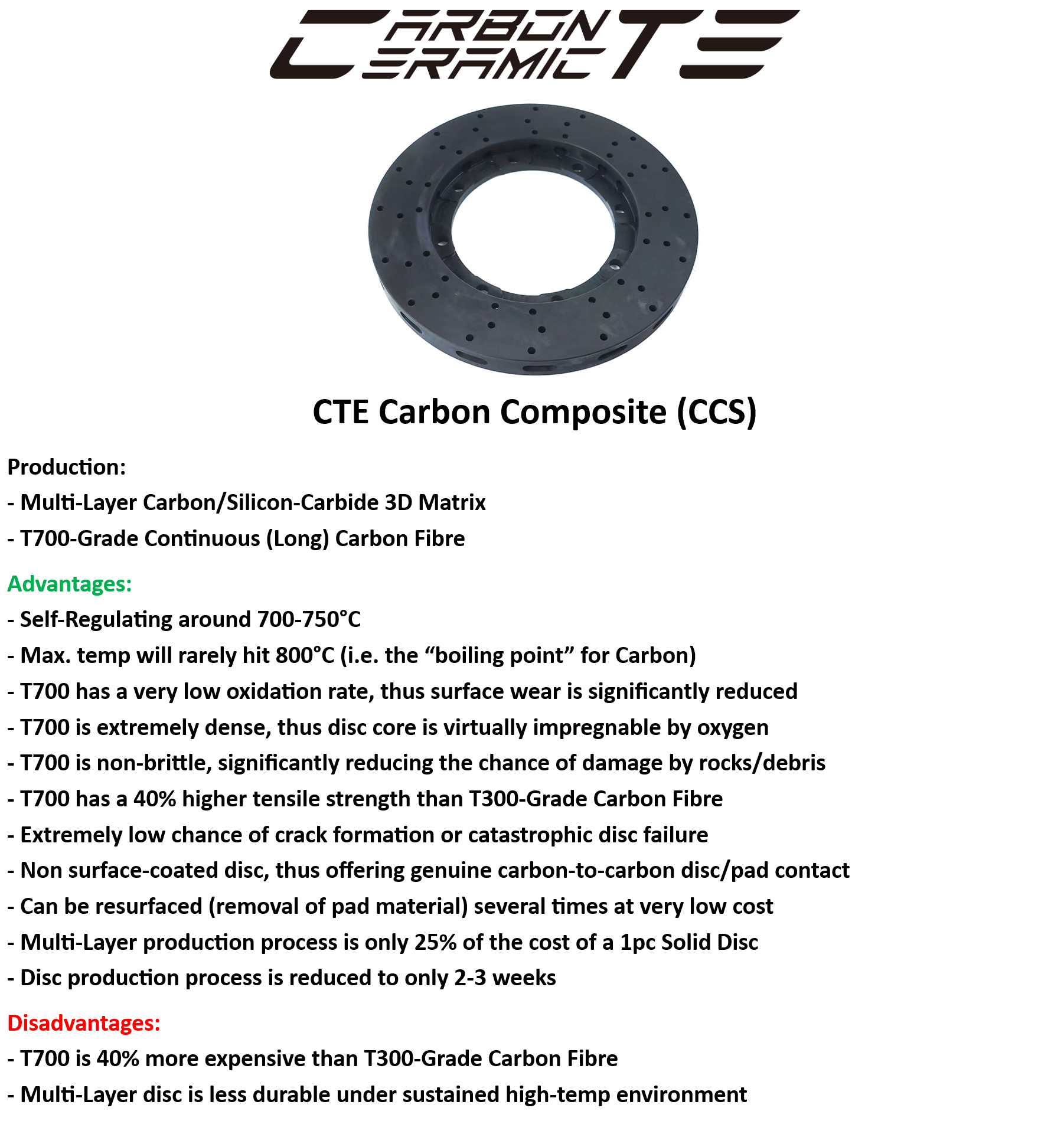

- CCM - These discs are manufactured from a fully three-dimensional matrix of CFRC and do not have an additional outer friction layer. Depending on the manufacturing process and type of materials used though, an additional outer coating may be applied. These are much less prone to oxidisation caused by high temperatures but may still suffer from premature wear and/or cracking caused by surface damage. As with the CCB's, if you notice a Carbon Ceramic Brake disc with surface cracks (even on a brand-new disc), stay well clear of it

- Discontinuous (Short) Carbon Fibre – These are basically “chopped” graphite fibres mixed with resin. This is the type of fibre used in the majority of Carbon Ceramic Brakes currently in use (almost all OE applications) due to significantly reduced manufacturing costs. This is what gives the distinctive “carbon flake” appearance on the surface of the discs (CCM from new, or CCB after the friction layer has worn down). Discs made with this type of material are “one-time-use only”, which means, once they wear and/or crack, it’s just an expensive paperweight

- Continuous (Long) Carbon Fibre – These are layers of woven carbon fibre, much the same as what you would expect to see on a Carbon Fibre aero component, but much more densely woven together into a 3D matrix. This is the type of fibre used in all “next-generation” Carbon Ceramic Brakes with a substantial increase in manufacturing cost. Instead of a “carbon flake” appearance, you now get a “woven fibre” appearance. Discs made with this type of material are much less prone to surface damage and/or cracking and can be resurfaced several times to an “as-new” condition. In addition, due to the higher friction coefficient, these type of discs give a much stronger “bite force” from cold

- T300 Grade – Wet spun, this is by far the most common grade of material used in the automotive industry due to its high tensile strength, durability and relatively low cost

- T700 Grade – Dry-wet spun, this grade is used primarily in the high-precision Aerospace sector and has a tensile strength approximately 40% greater than the T300 grade. It is slightly thicker and much denser per volume than T300, but also slightly heavier. Components made from this grade benefit from a much-reduced rate of wear due to a substantially decreased rate of oxidisation (T300 oxidises at twice the rate of T700 at high temperatures), have a much smoother surface texture (almost like a coating) and are non-brittle in nature (T300 is brittle). This is not a commonly used grade in the automotive sector due to its significant increase in cost (40% more than T300)

- All our brake discs are CCM, thus are much less prone to premature wear and/or cracking

- We use Continuous (Long) Carbon Fibre, thus can be resurfaced 3-4 times over the lifespan of the disc

- We use T700 Grade, thus do NOT require to surface coat our discs as our discs are non-brittle by nature

- Non Surface-Coated Discs offer genuine Carbon-to-Carbon disc/pad contact. Inferior discs with a Ceramic Outer Surface Layer offer negligible braking performance benefit over regular Iron discs

- Dynamic Test Simulations on our in-house Link & Horiba Brake Dynamometers ensure optimum performance under ALL conditions

- We have achieved 100% “Vertical Integration”, which means all of our consumer-grade products benefit from “Economies of Scale” due to our OE Automotive and Governmental Aerospace contracts i.e Our competitors cannot compete with us on price

- All of our bells are machined from Forged 6066-T6 Aluminium (not the cheaper 6061-T6 as commonly used by our competitors)

- We use our patented fastener mechanism, consisting of larger M8 bolts (not the common M6 used by our competitors) forged from Stainless A4-70 grade steel

- We are the only CCB manufacturer actively pursuing TUV certification of our discs

- We hold a vast amount of “ready stock” of our disc cores covering 290-440mm sizes, whilst all of our Aluminium (or steel, depending on application) bells are custom-made to order (yes, we can laser-etch your name/logo) with a 1-2 week lead time

If you have any questions at all, please feel free to Contact Us.