Carbon Fibre Reinforced Carbon (Carbon/Carbon or CFRC) is a high-strength composite that consists of a carbon or graphite matrix, fortified with very strong carbon fibres. There are a wide variety of carbon composite material types. The material is mainly used in highly demanding high-temperature applications.

Carbon Fibre Reinforced Carbon (Carbon/Carbon or CFRC) is a high-strength composite that consists of a carbon or graphite matrix, fortified with very strong carbon fibres. There are a wide variety of carbon composite material types. The material is mainly used in highly demanding high-temperature applications.

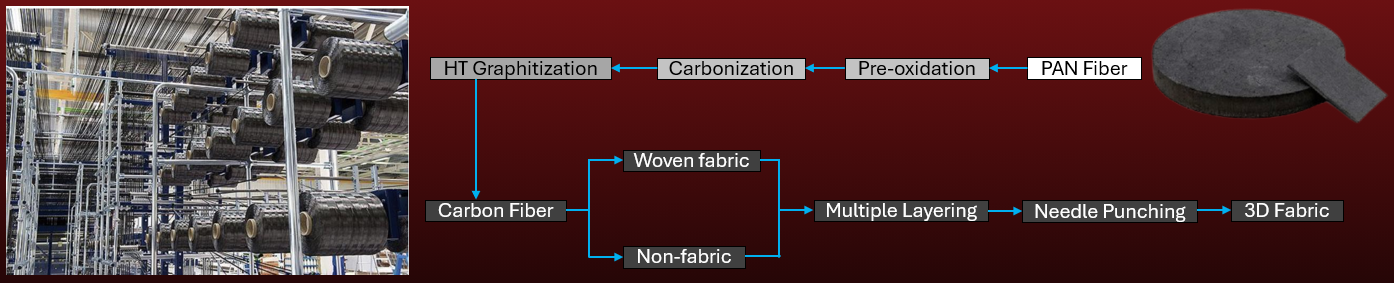

Carbon fibre, also known as graphite fibre, is a type of advanced material that has revolutionised various industries due to its exceptional strength-to-weight ratio and unique properties. It is a form of carbon with extremely high stiffness and tensile strength, making it an ideal reinforcement material for composites.

CTE interweaves T700s-grade continuous (long) carbon fibre sourced from Toray Japan to form a 3D multi-directional matrix, producing a stronger and more durable product, helping to keep brake system temperature down with stable & consistent performance.

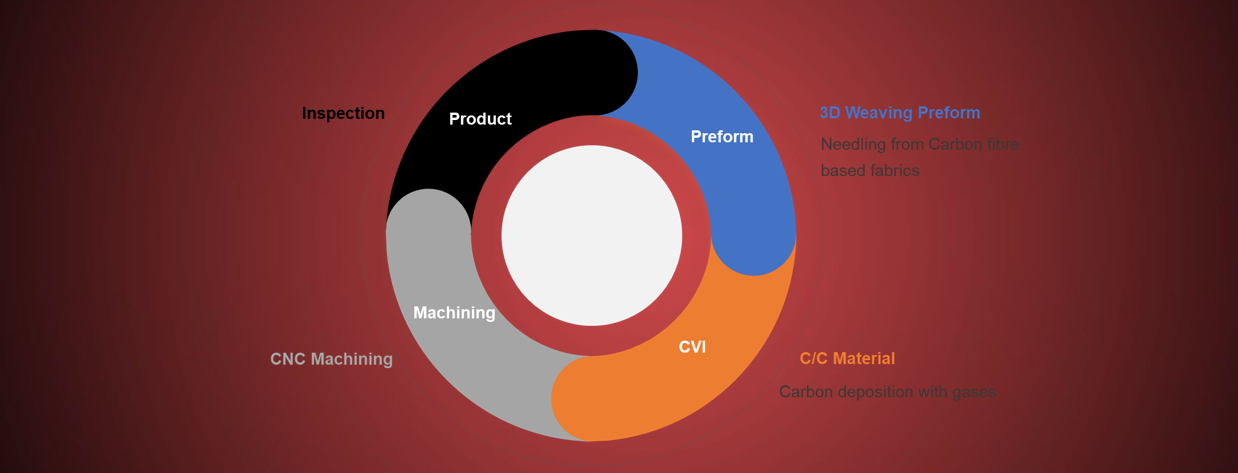

Brief Manufacturing Process of CTE’s Carbon/Carbon Friction Discs

Multiple Chemical Vapour Infiltration (CVI) steps may be performed as required.

3D Preform by Unique Needling of Carbon Fibre

CTE’s friction discs are made using carbon fibre based 3D fabrics which are prefabricated by a needle-punching process. A unique 3D structure of carbon fibre is woven together from multiple layers of continuous fibre cloth to form the base carbon material (preform).

Chemical Vapour Infiltration to form the Carbon/Carbon Material

CTE have developed over the past several years a proprietary Chemical Vapour Infiltration (CVI) method of Ceramic Matrix Composite (CMC) fabrication, whereby reactant gases diffuse into the porous preform to form a deposition.

Deposited material is the result of a chemical reaction occurring on the fibre surface. The deposition fills the space between the fibres, forming a composite material composed of the matrix (the deposited material) and the fibre preform (the dispersal phase).

Additionally, a heat treatment process will be used to initialise graphitization, whereby the preform is heated to 3000°c in order to eliminate non-carbon elements from the preform, rearranging the atomic structure into a highly ordered and dense 3D crystalline structure.

Manufacturing Carbon/Carbon Composites

Our innovative CVI solution provides an environment for controlled gas injection mechanisms, temperature control and vacuum conditions, helping to produce Carbon/Carbon (C/C) composite materials by depositing carbon-rich materials onto a designated carbon-based substrate.

Carbon/Carbon composites are heat-resistant, lightweight and high-strength, properties that make them suitable for many types of components.

Our Carbon/Carbon friction applications include, but not limited to, performance brake discs and clutch discs.

If you have any questions at all, please feel free to Contact Us